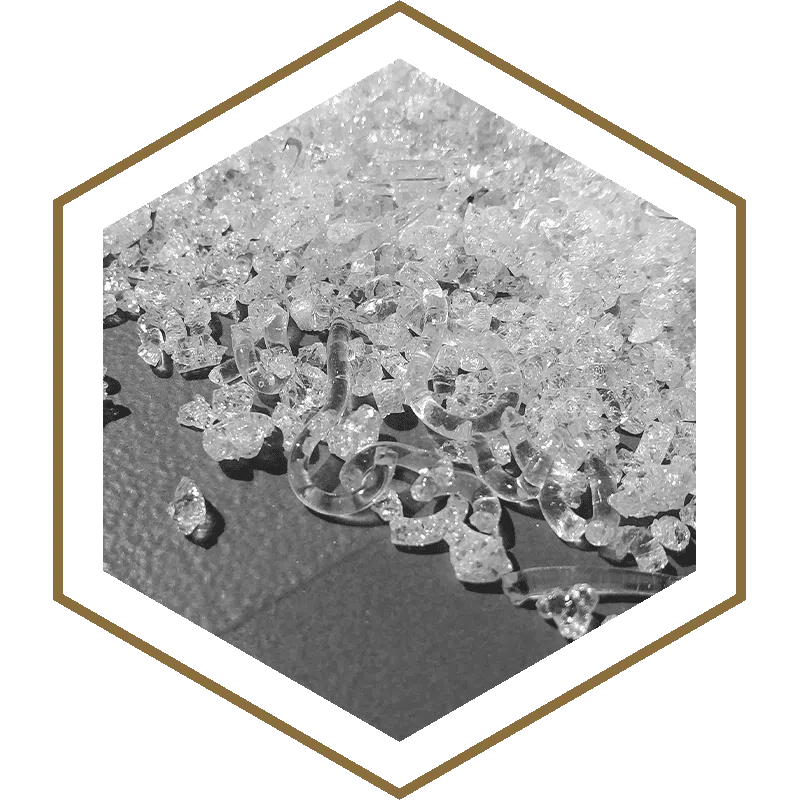

Ceramic grits is made up of glass particles, with a precise particle size distribution, which are applied on a ceramic surface to obtain different effects through appropriate firing.

What distinguishes the different ceramic grits is not only the particle size distribution, but also the origin of the raw materials and the composition. This significantly influences the chemical-physical properties of glass in terms, for example, of yield of the colors, temperatures, characteristics, thermal expansion coefficient values, presence of porosity etc …

To obtain the required final effect, a ceramic company often does not use a single grit, but mixtures of different grits to modulate the properties of the final glass layer.

Grain size: an essential aspect of grits

The particle size plays a basic role in the production of ceramic grits.

Several important properties derive from this physical/chemical characteristic:

- Reactivity in sintering and firing reactions.

The features are:

- softening temperature

- temperature ½ sphere

- melting temperature

- Smoothness in the application phases for correct distribution on the surface to be coated.

- Result of the surface required by the desired ceramic effect.

Current development of grits

Grits and micro-grits currently represent some of the most interesting products because they are very versatile. The several application possibilities and the different intrinsic characteristics allow to satisfy every market need, obtaining even very different surface results.

Sicer grits

The grit is a concentrate of chemistry at the service of the beauty and uniqueness of the finished product.

Sicer produces a wide range of technical grits and micro-grits and their excellent quality is the result of the know-how that characterizes the preliminary research phases and production processes.

The company offers different particle sizes according to the application technology used and the desired result.

Among Sicer grits there are the technical ones, transparent, matt, semi-matt, more or less glossy, reactive, effective and suitable for any ceramic cycle.

They allow the ceramic producers who use them to differentiate their products and to obtain unique aesthetic results and qualitative performances.

Different grits for different results!

Specifically, Sicer offer of grits and micro-grits consists of the following products:

- The series of technical floor grits GHR allows the customer to create a wide range of natural surfaces, pleasant to the touch and anti-reflective. They guarantee an excellent development of the color of the digital graphics and an innate naturalness.

- The neutral GRA grits are characterized by the materiality of the product that allows single use or customization through different mixtures and effects.

- GRA-DRY LUX grits are an exclusive series of grits for dry application for lapping/ mirror polishing. A range of compact transparent grits designed to ensure total transparency and brilliance, an incredible depth of the glass and a precise expansion coefficient.

- The colored grits of the GRC series can be used individually or in combination with other grits of the GHR or GRA series. The coloring is in fusion or in mass.

- The GRS series presents grits, offered in different grain sizes, with different effects, including: special metallized GSM grits and GRT reactive titanium grits.

Sicer grits are designed to be compatible with the entire range of basic products offered by the company.

Other fundamental aspects are the attention and respect for the environment that Sicer always takes into particular consideration in all phases of research and industrialization of its products.

The company is pursuing a sustainable development policy by focusing on the reduction of harmful emissions, waste and residues, and on constant reactivity in adapting to changes in the hazard classification of substances.A concrete example of these efforts is the patented Low Emission series, a complete range of environmentally friendly products.

Differentiation and “knowing how to stand out” as success factors

The rapid spread of digital decoration is opening up new markets to the graphic sector and to suppliers of raw materials for ceramic companies. Today they are able to offer exclusive solutions for effects and decoration potential.

The risk of spreading digital printing in the world, however, could, according to some people, decrease the exclusivity of Italian ceramics, damaging the made in Italy.

The entire ceramic production world has digital printing lines and technologies are increasingly the same; today the risk of having uniform ceramic products in all countries is always higher!

In defense of the uniqueness and quality of “Made in Italy”, suppliers of raw materials for ceramic companies play a fundamental role. They research and develop material applications that make it possible to enrich and differentiate surfaces, in addition to digital printing.

Sicer, thanks to constant investments in research and development, has distinguished itself and developed its own grits with the idea of focusing on products that would make the ceramic decoration unique in its kind.

The company is aware that it is the applications of very special and high quality materials that make the difference in the final product offer. This concept is valid today more than ever: the digital 4.0 revolution of the ceramic process contributes to making the ceramics splendid, but all tend to be uniform.

In the case of Sicer, therefore, the grit can be seen as an innovative concept that combines the technical properties and the particularity of the materials without overlooking the design, to create unique artifacts.

As always, Sicer has followed the philosophy of differentiation, of personalization, without ignoring the other two main themes of its business: the search for high product performance and customer satisfaction.

Frequently asked questions

Ceramic grits are micro glass particles used to impart aesthetic effects, special textures and improve the surface properties of ceramic tiles. Due to their chemical composition, they offer advantages such as high wear resistance and hardness.

There are two main application methods: wet or dry application using digital glue. Digital application allows precise and defined graphic details to be obtained.

Technical grits are designed to improve the performance of the ceramic surface, such as abrasion resistance and anti-slip. Decorative grits, on the other hand, are used to create unique visual effects and customise tiles with different levels of transparency and shininess.

Grit size, that is the dimension and distribution of the particles, is very important because it influences the reactivity during firing and the final aesthetic quality. Different particle sizes make it possible to modulate the aesthetic effect and technical properties of the ceramic surface.

The use of grits in combination with digital glue makes it possible to achieve very precise and detailed decorations while reducing material consumption. This method also offers the possibility of creating complex graphic effects and three-dimensional textures on tiles.