In an ever-changing world, where technology is evolving at such a rapid pace and competition is becoming increasingly fierce, companies that want to thrive must necessarily embrace technological innovation. However, for technological innovation to be successful, it is essential to invest in employee training. These new resources are not just simple tools, but require specific skills to be used effectively. An inadequately trained employee may not be able to exploit the full potential of the technology, wasting the initial investment. Employee training should be seen as an ongoing and continuous process, capable of accompanying employees in technological evolution and providing them with the skills they need to face the challenges of the labor market.

Sicer is a virtuous example of how technological innovation can be used to improve competitiveness and business success, combining economic growth and environmental respect. In this article, we will see which new technical tools the historic manufacturer and supplier of raw materials for ceramic companiesof Ubersetto has introduced in recent years in its laboratories and how the company invests in continuous employee training to ensure that employees are able to make the most of new technologies and maximize their benefits.

Why is innovation important?

The introduction of new technologies within a company can lead to several opportunities, including:

- Improved process efficiency: automating repetitive tasks and using advanced software can speed up activities and reduce errors.

- Increased productivity: employees can focus on more strategic and creative tasks, with a consequent increase in output.

- Reduced costs: process optimization and waste elimination can lead to significant economic savings.

- Reduced environmental impact: the adoption of more advanced technologies can allow for smarter resource management, such as optimizing energy consumption and reducing waste of raw materials.

- Creation of new products and services: innovation allows companies to respond to changing market needs and intercept new business opportunities.

The adoption of new technologies requires an initial investment, but the long-term benefits can be significant. Companies that invest in technological innovation are more likely to prosper in the future and achieve lasting success. Of course, it is important to choose the technologies that are right for the specific needs of the company and its sector. Let’s now see in detail which technical tools Sicer has chosen to introduce in its laboratories, Technology Lab and Digital Lab.

Innovation without limits: Sicer’s new technologies that are revolutionizing the ceramic industry

Sicer has always been distinguished by its constant drive for innovation. With a keen eye on the future and sustainability, the manufacturer and supplier of raw materials for ceramic companies of Ubersetto has recently introduced a series of cutting-edge new technologies into its laboratories that promise to revolutionize the industry.

Electronic microscope

Exploring the structural details of the surface of materials at very high magnification is essential to better understand how the various components of the ceramic product interact with each other once they are joined during firing. In this sense, the electronic microscope is an essential technical tool available to specialists in Sicer Technology Lab. By irradiating the sample with a beam of electrons, a magnification of the surface of the material being analyzed is obtained that is unattainable by means of simple optical magnification. This allows for a more detailed analysis of those imperfections previously recorded through the more classic optical microscope.

Here are the main features:

- Maximum resolution: 5 nm

- Maximum magnification: 150,000 X

- Two SE & BSE detectors

- Integrated EDS

Optical dilatometer

The optical dilatometer is an essential technical tool used by Sicer Technology Lab to analyze the evolution of the ceramic support as temperature conditions change. This allows the identification of the semi-finished products most suitable for the development of the finished product, based on the specific firing conditions that will then be present in the final customer’s plants. In particular, the optical dilatometer, in addition to measuring the coefficient of expansion, also allows for the study of the pyro plasticity of the paste, its sintering processes and the dilatometric coupling between the support and the layers of engobe/glaze/grits.

Optical microscope

The creation of images using a digital optical microscope is an essential technical tool for the in-depth analysis of ceramic material within Sicer Technology Lab. Through this advanced instrumentation, it is possible to analyze, both cold and during firing (up to 1500°C), the imperfections of the ceramic artifact as well as the particles contained in the raw materials, semi-finished products or inks, or those “foreign”.

The main technical characteristics are:

- Magnification up to 6000 x

- Ability to couple a micro oven to analyze the fusion process up to 1500°C

- Integrated display and software for better visual analysis

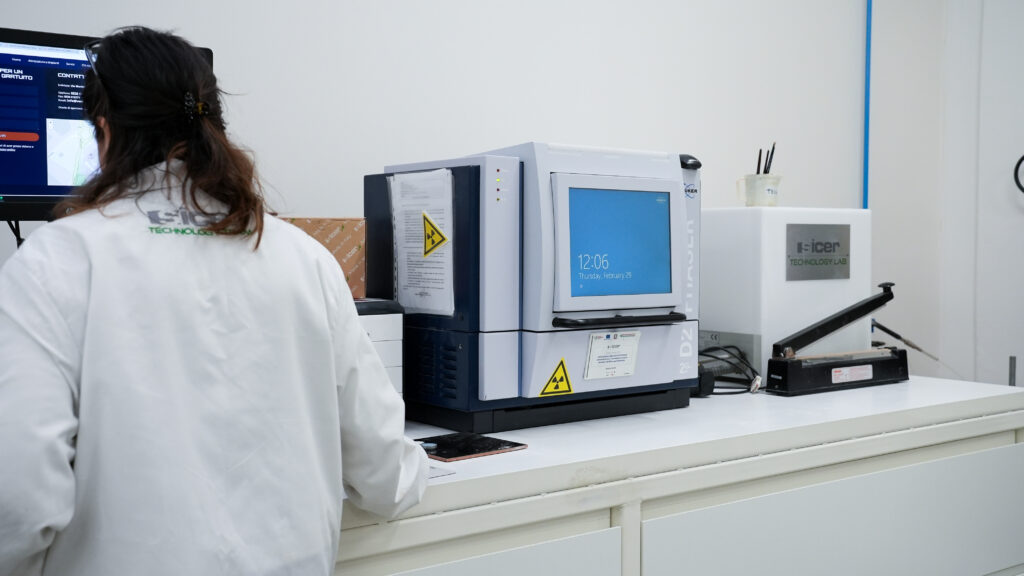

X-ray diffractometer

Crystallographic analysis is essential to evaluate the nature of raw materials and to understand the structure of ceramic sheets or tiles. This, in turn, allows for the improvement of the technical and aesthetic characteristics of the finished products based on the commercial purposes of the customer and the peculiarities of their production plants. For this purpose, the diffractometer, used by Sicer Technology Lab, becomes essential for this type of analysis. Using an X-ray source, this machine can identify the presence of various minerals (quartz, feldspars, clays, etc.), as well as estimate their concentration. The analysis can be carried out, in addition to the powders of raw materials, on the ceramic support, the engobe/glaze/grit layer both before and after firing.

In addition to this, the XRD technique coupled with elemental analysis by fluorescence can also estimate the amorphous fraction, i.e., the glassy component characterized by the absence of crystalline phases. The main technical characteristics are:

- Automatic sample changer (up to 6)

- Associated software with a database for the semi-automatic recognition of crystalline phases and their quantification using the Rietveld method.

Pendulum

The coefficient of friction of a surface is a fundamental characteristic in the ceramic world. The pendulum is the technical tool used by Sicer Technology Lab to measure this parameter. Once the wet sample is placed on the platform, the pendulum is allowed to swing over it, obtaining a value from 0 to 100 during contact between the sample and the sliding device located on the tip of the pendulum. This value indicates the resistance to slip on the surface of the sample.

Rotational rheometer

The rotational rheometer is a technical tool available to Sicer Digital Lab with which specialized technicians test digital glues and inks on a daily basis. Their goal is to better understand the interaction of the components of these digital products and the relationship between stress and strain in a flowing material, even at high viscosity. These characteristics are of great importance as they must meet very rigid standards, linked both to regulations and to the production techniques of the final customer. How does it work? The material to be studied is placed on a plate or inside a cup; a mechanical force is applied to the substance by means of a suitably designed rotor depending on its viscosity, in order to stress the material. Based on how the material responds to the applied force, it is possible to understand the rheological behavior of flow and parameters such as viscosity, yield stress, thixotropy, etc.

The main features are:

- Availability of different rotor geometries to characterize samples in a very wide viscosity range

- Possibility of controlling the temperature in a wide range with customizable heating and cooling ramps

Laser granulometer

The consistency and particle size distribution of inks and adhesives are fundamental characteristics in the ceramic sector, as they must be precisely calibrated to the needs and characteristics of the individual machines of the end customer. The Laser Granulometer, available to the specialized technicians of Sicer Digital Lab, serves precisely this purpose. Two laser beams are directed through a pair of lenses aligned with a series of detectors. The sample, in liquid or solid form, is irradiated by the lasers; the detectors collect the energy of the beam, producing a particle size distribution curve based on the light deflection angle.

Its main features are:

- Particle size from 0.01 to 3500 um

- Automated sample dispersion in a solvent

- Possibility to analyze solid samples

Sedimentation measurement system

Every digital ink or effect is composed of a liquid part (solvent mixture), a solid part (pigment or material) and a dispersing component. The latter’s fundamental task is to keep the suspension of submicron solid particles within the liquid as homogeneous as possible: the Turbiscan Tower, used by Sicer Digital Lab, provides very useful information for monitoring this characteristic. Its operation is based on the measurement of light transmission and backscatter through the ink, to detect and quantify the sedimentation process of the solid part.

The main technical characteristics are:

- Study of 6 samples at a time

- Thermostatic chamber from 4° to 80°C

- Detection of destabilization phenomena up to 200 times faster than the human eye

Staff training: an investment for the future

Staff training is a fundamental component of the success of any company. In a constantly evolving work environment, where the required skills change rapidly and technology relentlessly advances, investing in the professional growth of one’s employees becomes an essential strategic choice.

Training activities take on several forms, from traditional courses to immersive workshops, from front-end seminars to online learning programs. The ultimate goal is always the same: to provide employees with the tools they need to do their jobs effectively and contribute to achieving business objectives.

The benefits of corporate training extend to both individuals and the entire organization. For employees, it represents an indispensable opportunity to acquire new skills and stay up-to-date on the latest industry technologies, strengthen their skills and professionalism, take on new challenges and advance their careers, increase self-confidence and motivation, improve productivity and work performance. For the company, training translates into a series of tangible benefits, including a more qualified and competent workforce, better adaptation to market changes and new challenges, increased productivity and efficiency, reduced errors and costs, a better corporate climate and greater collaboration and employee loyalty.

Sicer has embraced the philosophy of continuous learning for a long time. Through a wide range of training courses, workshops and personalized development programs, the company invests in the growth of its staff, creating a culture of value and innovation.

Frequently asked questions

Technological innovation makes it possible to improve process efficiency, increase productivity, reduce costs, and minimise environmental impact. It also allows new products and services to be developed to better meet market needs.

Sicer uses advanced technologies such as the scanning electron microscope, optical dilatometer, X-ray diffractometer, rotational rheometer and laser granulometer, which are essential for precise analysis and development of advanced ceramic products.

Investing in training enables employees to acquire up-to-date skills, improve productivity, reduce errors, and adapt to new technologies, strengthening business competitiveness.

This instrument helps to identify the most suitable materials for firing by studying thermal expansion and other parameters such as pyroplasticity and sintering processes.

Sicer optimises the use of resources, reduces waste, and develops technologies that improve energy efficiency, integrating sustainability and economic growth.