Index

- Introduction

- What is lapped porcelain stoneware?

- The lapping production process

- Technical characteristics and performance

- Differences between tumbled stoneware, natural stoneware, and other finishes

- Advantages of lapped porcelain stoneware

- Disadvantages and technical limitations

- Technologies and innovations in the sector

- Quality control and industrial testing

- Industrial applications and areas of use

- Conclusions

- FAQ

Introduction

In the industrial ceramic finishes sector, lapped porcelain stoneware stands out for its ability to combine high technical performance with refined aesthetics. This type of surface is the result of a highly specialized production process called lapping, which produces tiles with controlled shine and a unique texture.

Unlike completely glossy or natural finishes, lapped porcelain stoneware is an intermediate solution that meets the requirements of durability, ease of cleaning, and visual appeal. The market’s growing interest in technically advanced and visually appealing surfaces has contributed to the spread of this material, which is now widely used in high-end residential settings as well as in commercial and industrial contexts with heavy use.

For laboratory technicians and R&D managers in ceramic companies, understanding the nature of honoured porcelain stoneware in detail is essential for optimizing processes, choosing the right formulations, and ensuring consistent performance over time. In this article, we will take an in-depth look at all the characteristics of the material, the production stages, the advantages, and the limitations of its application, offering an up-to-date and rigorous guide designed for professionals in the sector.

What is lapped porcelain stoneware?

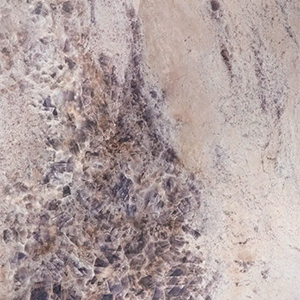

Lapped porcelain stoneware is a special type of surface obtained by partially polishing the tile, which gives the ceramic surface shine and controlled reflection without reaching the mirror-like finish of a fully polished surface. It is therefore a lapped ceramic surface halfway between a natural and a glossy effect, ideal for applications where it is necessary to balance aesthetic appeal and technical requirements.

The base material is technical porcelain stoneware, composed of a mixture of selected high-purity raw materials (kaolin, feldspar, silica sand) and sintered at temperatures above 1200°C. The result is a structure with very low porosity, high compactness, and mechanical resistance.

The lapping process takes place in the final stage of production: rotating head machines equipped with calibrated abrasives are used to treat the surface of the fired tile, removing micro-layers of the surface coating until a homogeneous and partially polished texture is obtained. This treatment is not only aesthetic, but also allows the degree of slipperiness and light refraction to be modulated, improving the performance of the material depending on the application.

Compared to other ceramic finishes, the lapped surface stands out for:

- Controlled light refraction, without a mirror effect.

- Surface uniformity, with a smooth but non-slip texture.

- Mechanical resistance unchanged compared to the greified base.

The technical parameters that characterize this surface include:

- Gloss unit: generally between 20 and 50 GU.

- Dynamic friction coefficient: can vary from R9 to R11 depending on the finish and treatments.

- Residual coating thickness after mechanical removal: a critical parameter for ensuring durability over time.

Understanding these aspects is essential for optimizing the choice of formulations and production cycles, especially in high-volume production or for markets that require high technical and quality standards.

The lapping production process

The lapping production process is a crucial stage in the manufacture of lapped porcelain stoneware, as it determines not only the final appearance of the surface but also its technical performance. Lapping is carried out on already fired tiles through a series of steps that require dedicated equipment, strict control parameters, and cutting-edge technologies.

Process stages

- Loading the tiles: the supports are placed on automated lines.

- Pre-lapping: coarse abrasives remove the outermost layer of the glaze.

- Intermediate lapping: smoothing heads with progressively finer abrasives are used to homogenize the surface.

- Final polishing (optional): depending on the desired degree of shine, specific polishing pastes are applied.

- Cleaning and drying: removal of residues and visual inspection.

- Surface protection, if required: application of water- and oil-repellent layers.

Machinery and equipment

The main machinery for ceramic lapping includes:

- Roller or satellite heads with diamond abrasives of different grit sizes;

- Washing and suction systems for dust removal;

- Optical sensors and scanners for automatic flatness and gloss control;

- Cooling and roller conveyor tables for integration into the continuous cycle.

Modern lines are often equipped with integrated automation and digital monitoring systems that allow precise control of processing parameters.

Control parameters

During lapped ceramic production, certain parameters must be constantly monitored:

- Slab feed speed;

- Abrasive head contact pressure;

- Temperature of the cooling lubricants;

- Number of passes and dwell time per phase;

- Uniformity of the machined surface (in-line optical scanning).

The balance between these factors is essential to avoid phenomena such as overlapping (excessive removal) or loss of flatness.

Innovative technologies

Today’s advanced lapping technologies integrate:

- Numerical control of machines to modulate pressures in real time;

- Long-lasting, eco-friendly abrasives with lower environmental impact;

- Self-calibrating software for adaptation to different formats and thicknesses;

- Integration with MES systems for real-time tracking of production data.

These innovations make it possible to increase production efficiency, reduce waste, and ensure a consistently high standard of quality, even on large batches.Overall, lapping is a strategic, high-tech process that must be precisely calibrated for each production line according to market requirements and the technical specifications of the finished product.

Technical characteristics and performance

The technical characteristics of lapped porcelain stoneware are a key factor in its selection for industrial, contract, and commercial applications. The combination of physical and mechanical performance and aesthetic appeal makes it a versatile and reliable material. Below we analyze the most relevant performance parameters.

Degree of gloss and light reflection

One of the most appreciated features of lapped stoneware is its degree of shine, obtained by partially polishing the surface. The gloss unit (GU) index can vary:

- From 20 to 30 GU for matt-tumbled finishes;

- Over 40 GU for semi-gloss finishes;

- Up to 60 GU for deeply lapped products.

This variability allows the surface to be adapted to the project requirements, balancing light reflection and visual comfort, especially in indoor environments with artificial or directional lighting.

Wear resistance and durability

Porcelain stoneware is by nature one of the most abrasion-resistant ceramic materials. If properly calibrated during processing, the lapped surface maintains excellent levels of wear resistance even after years of heavy foot traffic. In accordance with UNI EN ISO 10545-7, PEI 4 and PEI 5 values can be obtained, with weight losses of less than 0.1 mg for cycles of 6,000 revolutions on standard surfaces.

Durability is also guaranteed by:

- Low surface porosity;

- Absence of post-lapping micro-cracks;

- Dimensional and planar stability.

Specific physical-mechanical properties

From a physical-mechanical point of view, the mechanical properties of lapped stoneware depend on both the substrate and the surface layer. The main indicators include:

- Breaking strength > 35 N/mm²;

- Breaking load > 1300 N on standard 10 mm slabs;

- Mohs hardness ≥ 7, even after lapping treatment.

The absence of open porosity, combined with a controlled expansion coefficient, contributes to making the material suitable for applications in environments subject to thermal stress or variable humidity.

Friction coefficients and slip resistance classifications

One of the most critical aspects concerns the slip resistance of the lapped surface, which can vary depending on the degree of polishing. The most common slip resistance classifications include:

- R9: for semi-gloss indoor surfaces with low traffic;

- R10–R11: for public and commercial environments with moderate slip risk.

The dynamic coefficient of friction (DCOF) is often between 0.35 and 0.45, depending on the finish and any surface treatments applied. Advanced products such as Sicer GRA DRY-LUX grits combine high gloss with optimal friction and chemical resistance values.

This combination of parameters confirms lapped porcelain stoneware as a high-performance solution for applications where aesthetics, safety, and technical performance must coexist.

Differences between honed, natural, and other finishes

When considering the various types of stoneware surfaces, it is essential to distinguish between the main variants available on the market in order to correctly assess their performance and areas of use. Comparing lapped porcelain stoneware with other finishes – such as natural, polished, satin, or textured – helps technicians and R&D managers identify the most suitable product for the application in question.

Lapped vs. natural surface

Natural stoneware has no post-firing surface treatment: it has a matte finish, is rough to the touch, with excellent grip and good wear resistance. In contrast, lapped porcelain stoneware undergoes a mechanical treatment that modifies the surface refraction, offering a more elegant and contemporary semi-gloss effect.

Main technical differences:

- Friction: higher in natural (R11-R13), more variable in lapped (R9-R11);

- Shine: absent in natural, adjustable in tumbled;

- Aesthetics: textured and technical in natural, sophisticated and reflective in tumbled;

- Maintenance: easier in the tumbled finish, which has a more compact and less porous surface.

Comparison with glossy, satin, and textured finishes

- Full gloss: obtained by glazing or extreme polishing, it has high brilliance (GU > 80) but low slip resistance. It is not recommended for high-traffic public areas.

- Satin: velvety and matt surface, more uniform to the touch, ideal for elegant environments but subject to moderate stress.

- Textured: raised patterns and textures for maximum grip, used outdoors, in wet areas or on ramps. It has excellent slip resistance but is more difficult to clean.

Comparative performance and application parameters

| Type of finish | Gloss Unit | Friction coefficient (DCOF) | PEI | Ideal context |

| Lapped | 30–60 | 0.35–0.45 | 4–5 | Technical/residential interiors |

| Natural | <20 | 0.55–0.70 | 4–5 | Exteriors, high-traffic areas |

| Glossy | >80 | <0.30 | 3–4 | Light residential |

| Satin | 10–30 | 0.45–0.55 | 3–4 | Elegant interiors |

| Textured | <15 | >0.70 | 4–5 | Outdoor, technical flooring |

Technical selection criteria

The choice between honed stoneware and other ceramic finishes must be guided by:

- Environmental conditions (indoor/outdoor, dry/humid);

- Expected traffic levels;

- Aesthetic requirements of the project;

- Safety and anti-slip regulations;

- Ease of maintenance and routine cleaning.

Lapped porcelain stoneware is the ideal compromise for those seeking high performance without compromising on surface elegance. The variants offered by manufacturers such as Sicer, thanks to the quality of the grit and the precision of the melting and grain size parameters, guarantee repeatable results that comply with the quality standards required by the professional market.

Advantages of lapped porcelain stoneware

Lapped porcelain stoneware offers a combination of aesthetic qualities and technical performance that make it one of the most popular ceramic finishes for use in environments with high design and technical value. Let’s take a closer look at the main advantages of lapped stoneware for the ceramic industry and designers.

Aesthetic properties and design versatility

One of its most recognized strengths is its ability to combine the aesthetics of a glossy surface with a more technical and contemporary look. The degree of gloss can be adjusted, allowing the underlying digital graphics to be enhanced with a glass-like effect of controlled depth.

The lapped surface:

- Enhances the quality of digital decoration;

- Increases the perception of cleanliness and order in rooms;

- Suitable for minimalist, industrial, luxury, or retail projects;

- It is available in numerous colors and graphics.

Thanks to this aesthetic versatility, lapped stoneware is suitable for both design collections and large-scale technical production.

Superior mechanical resistance and durability

Despite the surface treatment, lapped stoneware maintains the mechanical properties of the porcelain substrate:

- High resistance to bending and load;

- Excellent abrasion resistance (PEI 4-5);

- Compactness and dimensional stability.

The use of highly transparent technical grits, such as Sicer’s DRY-LUX GRA, allows for compact, non-porous surfaces that are able to withstand intensive foot traffic and thermal stress over time.

Easy maintenance under normal conditions

Cleanability is another key advantage: the smooth surface and reduced microporosity allow for quick routine maintenance using neutral detergents. Unlike textured or natural surfaces, lapped stoneware:

- Retains less dirt and dust;

- Does not require intensive protective treatments;

- Is easy to clean even in commercial environments.

Adaptability to different architectural applications

Lapped porcelain stoneware can be used in a wide range of contexts, from interior wall coverings to technical flooring and decorative wall elements. Thanks to its performance profile, it is perfectly suited to:

- Contract and retail environments;

- High-end residential spaces;

- Halls, showrooms, and executive offices;

- Large formats and continuous surfaces.

For designers, it represents a balanced solution between aesthetics, safety, and functionality, with a good margin for customization through a mix of formats, decorations, and surface textures.

These advantages explain why lapped stoneware is now one of the most popular finishes for projects where architectural image is an integral part of the material’s technical performance.

Disadvantages and technical limitations

Despite its many advantages, lapped porcelain stoneware has some technical limitations that must be carefully evaluated during the design phase, especially in relation to the application context and long-term maintenance requirements.

Greater visibility of fingerprints and surface marks

One of the most frequent issues concerns the visibility of marks, fingerprints, and footprints. Due to its partial polishing, the lapped surface tends to reflect light more than natural stoneware, highlighting:

- Traces of dirt;

- Damp footprints;

- Micro-scratches from dragging.

These effects are amplified on dark-colored surfaces, where aesthetics can be compromised without regular cleaning.

More frequent maintenance required

Although the material is easy to clean, more constant maintenance is required than for other more opaque or textured finishes in order to maintain its shiny appearance. In high-traffic public or commercial settings, the following may be necessary:

- Daily use of neutral detergents;

- The use of microfiber cloths to avoid residue;

- Periodic water- and oil-repellent treatments in critical areas.

Limitations in high-traffic environments

In some industrial, manufacturing, or public environments with high foot and vehicle traffic, the lapped surface may be subject to:

- Greater surface wear over time;

- Reduction in slip resistance in the presence of liquids;

- Risk of loss of shine on large areas that are not adequately treated.

In these cases, it is preferable to consider structured or natural finishes, which are more suitable for withstanding intensive loads without performance degradation.

Considerations on slip resistance coefficients

From a safety perspective, it is essential to consider the slip resistance class of the surface. Lapped stoneware rarely exceeds R10 without the use of additives or post-production treatments. This may make it unsuitable for:

- Public wet areas;

- Ramps or external entrances;

- Environments that must comply with R12–R13 requirements.

To improve safety, technologies such as the following can be integrated:

- Invisible micro-reliefs;

- Technical anti-slip granules compatible with lapping;

- Transparent silica-based surface treatments.

In summary, while maintaining a solid technical base, lapped stoneware must be chosen carefully according to the installation environment and operational requirements. Understanding the disadvantages of lapped stoneware allows you to plan corrective and management solutions to optimize its use in industrial and design applications.

Technologies and innovations in the sector

The ceramic finishing sector is constantly evolving, driven by a strong research and development component and the demand for increasingly advanced aesthetic and functional solutions. Even lapped porcelain stoneware now benefits from numerous innovations in ceramic lapping, materials, and surface treatments.

New lapping technologies and surface treatments

Modern production facilities integrate:

- Multi-diameter heads with electronic control, allowing very fine adjustments of pressure and speed;

- Dry lapping systems, such as those used in Sicer’s GRA DRY-LUX grit cycles, to obtain mirrored surfaces without the use of water;

- Hydrophobic and antistatic surface treatments integrated into the production cycle, which improve cleanability and wear resistance;

- Self-learning software for defect recognition and maintenance of optimal working conditions.

These systems reduce energy consumption, increase productivity, and improve the repeatability of results.

Developments in materials and formulations

Enamel and grit formulations have evolved with the introduction of:

- Highly transparent glass with low thermal expansion coefficient;

- Functional additives that improve the bond between the coating and the substrate;

- Mixable grits capable of adapting to different grain sizes and operating conditions;

- Viscosity-controlled frits for homogeneous and continuous fusion.

The result is greater surface compactness and improved response to thermal and mechanical cycles.

Innovations to improve performance and durability

The latest innovations in the field of lapped ceramic production have led to:

- Reduction in surface microporosity, improving hygienic properties and chemical resistance;

- Increased surface hardness, with higher abrasion resistance values even after lapping;

- Long-term aesthetic stability, with less sensitivity to stains, scratches, and color variations.

The use of these solutions allows for the use of lapped stoneware even in high-stress environments.

Research and development in the ceramic finishes sector

Numerous research centers, in collaboration with the most advanced ceramic companies, are carrying out projects on:

- Automated systems for modulating gloss;

- In-line spectrophotometric analysis for continuous control of aesthetic performance;

- Functional nanotechnological treatments to increase durability without altering visual perception;

- Low environmental impact solutions for sustainable production cycles.

Sicer, in particular, has developed technical solutions such as the GRA DRY-LUX system, which offers high performance in terms of gloss, chemical resistance, flatness, and transparency, thanks to advanced formulations and careful grain size selection.

These innovations represent a strategic lever for ceramic companies that want to stand out on the market for quality, reliability, and ability to anticipate the design demands of the sector.

Quality control and industrial testing

The quality of lapped porcelain stoneware cannot be separated from rigorous quality control at every stage of the production cycle. To ensure compliance with technical requirements and market expectations, manufacturers must implement standardized verification systems based on international standards and established performance parameters.

Quality control parameters in production

During production, key parameters are monitored, such as:

- Flatness of the slab (using fleximeter sensors);

- Thermal expansion coefficient (compatibility between enamel, grit, and substrate);

- Uniformity of lapping across the entire surface;

- Gloss index (GU) measured on representative samples;

- Compactness and absence of micro-defects through visual inspection and optical scanners.

Quality depends on the synergy between formulation (frits and grits), application process, and precision of the finishing equipment.

Standardized tests for performance evaluation

The most commonly used tests for evaluating technical performance include:

- UNI EN ISO 10545-7: abrasion resistance (PEI test);

- UNI EN ISO 10545-4: flexural strength and modulus of rupture;

- UNI EN ISO 10545-13: chemical resistance to acids, bases and solvents;

- EN 16165: determination of slip resistance using the pendulum test (PTV);

- Spectrophotometric tests to check color variations between batches.

The use of Sicer’s DRY-LUX grits, for example, allows weight losses of less than 0.09 mg to be achieved even in PEI 4 cycles of 6000 revolutions.

Technical reference standards

Compliance with technical standards is essential to ensure:

- Safety of use (e.g., in public places);

- Compliance with specifications;

- Access to international markets with different standards (e.g., ANSI A137.1 in the USA).

In addition to ISO and EN standards, ceramic companies use voluntary certifications (e.g., ISO 9001) to demonstrate the reliability of their processes.

Methods of verifying compliance

Technical conformity is verified by means of:

- In-line checks (automation, sensors, artificial vision);

- Offline checks (quality laboratory with sampling);

- Periodic internal audits;

- Inter-batch comparative tests and quality history;

- Technical data sheets and laboratory reports attached to the product.

These tools ensure complete traceability and continuous improvement of the production cycle. For quality managers and laboratory technicians, having objective and comparable data is essential for releasing consistent, high-performance batches.

Industrial applications and areas of use

Lapped porcelain stoneware has established itself as one of the most versatile solutions in the ceramic surface sector, thanks to its ability to combine aesthetics, technical performance, and ease of maintenance. Its industrial and commercial applications cover a wide range of contexts, each with specific requirements in terms of performance, safety, and durability.

Technical considerations for different uses

The choice of honed stoneware must take into account the operating conditions:

- In medium-traffic indoor environments, it offers excellent performance with low maintenance;

- In areas at risk of humidity (e.g., bathrooms, spas, entrances), the friction coefficient must be evaluated;

- In industrial or outdoor settings, structured finishes or lapping with integrated DRY-LUX technology with high-grip grit are recommended.

In every application, the use of a tumbled finish enhances the perception of quality and value of the space, while maintaining efficient management over time.

Selection criteria for specific applications

For an informed product selection, designers must consider:

- Expected level of foot traffic;

- Cleaning and maintenance requirements;

- Aesthetic requirements and brand image;

- Regulatory constraints (e.g., slip resistance);

- Compatibility with other materials and architectural finishes.

The versatility of lapped porcelain stoneware—especially when produced with advanced technical systems such as those offered by Sicer—allows for customization based on operating conditions and design expectations without compromising the durability and perceived quality of the covering.

Conclusions

Lapped porcelain stoneware is a high-tech ceramic solution that meets the aesthetic and performance requirements of professional, architectural, and industrial settings. Its main technical features—such as compactness, adjustable gloss, good wear resistance, and ease of cleaning—make it particularly suitable for projects that require a balance between functionality and image.

For laboratory technicians, R&D managers, and designers, it is essential to consider all the variables that influence the choice of this finish: from the type of ceramic substrate to the formulations of the grits, right through to the environmental conditions of use. In-depth knowledge of the lapping process, its technologies, and the associated quality tests allows for an informed selection geared towards maximum durability.

Looking to the future, there is a growing integration between automation, functional formulations, and environmental sustainability. Companies that invest in research and development, such as Sicer with its DRY-LUX grits, are charting the course towards increasingly high-performance, customizable surfaces that are compatible with low-impact production cycles.

Lapped stoneware, a trendy finish, is evolving into a new technical standard for the contemporary ceramic industry.

FAQ

FAQ

It is a type of porcelain stoneware tile that has undergone lapping, a mechanical polishing process that gives the surface a controlled shine, halfway between a natural and glossy effect.

Natural stoneware does not undergo post-firing treatments and has a matt, textured appearance. Lapped stoneware, on the other hand, is polished on the surface, making it more reflective and compact, but with lower slip resistance values.

It can be used in medium-traffic indoor environments, provided that the right technical grits are chosen and the friction coefficient (generally R9–R11) is verified. In very humid environments or those subject to R12–R13 regulations, it is advisable to opt for textured finishes.

Regular maintenance with neutral detergents is sufficient. To preserve its shine, it is advisable to avoid aggressive detergents and use microfiber cloths. In case of heavy traffic, periodic water-repellent treatments are useful.

When properly installed, it can guarantee a long life even in professional environments. Sicer’s GRA DRY-LUX grits, for example, offer chemical resistance, non-porosity, and excellent dimensional stability.

Yes. Thanks to its aesthetic versatility and compactness, it is also ideal for wall coverings, especially in commercial environments and office spaces where an elegant yet technical finish is required.

– Dry application with no waste;

– Deep, controlled shine;

– No porosity;

– High resistance to scratches and chemicals;

– Compatibility with different colors and ceramic models.

Lapped stoneware made with Sicer’s DRY-LUX technology is one of the most advanced solutions available today: it combines visual appeal, mechanical performance, and technical reliability for the ceramic industry.