Index

- Introduction

- Digitalization and advanced technologies

- Sustainability and environmental responsibility

- Low-emission digital adhesives and inks Sicer

- Innovation in design and market strategy

- Integration and practical applications

- Future prospects and challenges for the sector

- Summary table of innovations

- Conclusions

- FAQ

Introduction

Innovation in the ceramic sector is undergoing a profound transformation. Digitalization, new materials, and a focus on sustainability are expanding the aesthetic and functional potential of ceramics, while reducing the environmental impact of production processes.

The result is an industry that is increasingly integrated between technology, design, and sustainability, in which companies such as Sicer play a leading role thanks to constant research and the development of low-emission solutions.

Digitalization and advanced technologies

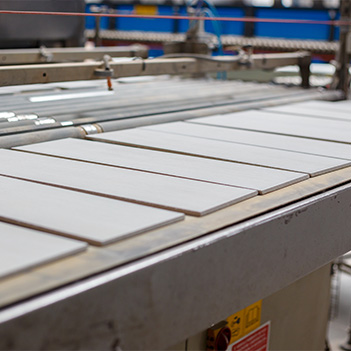

Digital inkjet printing has revolutionized ceramic decoration, offering greater precision, detail, and customization of designs. Integration with 3D printing and additive manufacturing now allows the production of complex shapes and functional surfaces that were previously unachievable.

At the same time, automation and advanced robotics improve efficiency and quality, reducing errors and consumption. In Italy, these innovations have strengthened the sector’s global leadership, enhancing the creativity and technical quality of Made in Italy.

Sustainability and environmental responsibility

Sustainability is now a strategic pillar for the ceramic sector. Companies are investing in recycling, emissions reduction, and low-impact production processes. Innovative products contribute to more energy-efficient buildings and a more transparent production cycle, thanks to environmental product declarations (EPDs) and ISO 14001 standards.

Sicer has been integrating these principles into its R&D processes for years, developing materials and technologies in line with the objectives of the UN’s 2030 Agenda.

Low-emission digital inks and adhesives Sicer

Among the most significant innovations introduced by Sicer are:

Low-emission digital inks

Available in two versions:

- Water-based, completely odorless and free of VOCs (volatile organic compounds);

- ECO solvent-based, with ultra-refined solvents that guarantee reduced odor emissions and color stability.

Laboratory tests confirm a reduction of up to 50% in VOC emissions compared to traditional formulations, improving air quality in the factory.

Water-based digital adhesives

Water-based digital adhesives represent a further step forward in sustainability applied to production:

- Significant reduction in TOC and aldehyde emissions;

- No unpleasant odors during application;

- Compatibility with existing production lines;

- Excellent adhesion even on highly absorbent surfaces.

Find out more about Sicer’s Low Emission collection and water-based digital adhesives.

Innovation in design and market strategy

Ceramic innovation is not just about technology, but also design. Today, it is possible to achieve structured surfaces, three-dimensional textures, and high-definition colors while maintaining high sustainability standards.

Sicer is constantly expanding its product range by integrating aesthetic research with the most advanced chemical formulations.On a strategic level, ceramic companies are adopting digital tools such as SEO, e-commerce, and advertising to communicate innovation and increase global visibility.

Integration and practical applications

The adoption of sustainable technologies no longer requires complex investments. Sicer’s low-emission solutions are compatible with existing systems and improve:

- machine cleaning and maintenance;

- the reduction of production downtime;

- color and quality stability of production;

- environmental control, thanks to integrated monitoring systems.

These advantages promote the transition to zero-waste production models, in line with ESG principles.

Future prospects and challenges for the sector

The future of the ceramic sector is based on three pillars:

- Continuous research into multifunctional materials and water-based processes.

- Energy efficiency, with optimization of printing and firing.

- Collaboration within the supply chain to reduce waste and transport.

European companies, and Italian companies in particular, maintain their global leadership thanks to heavy investment in R&D and an industrial culture focused on innovation and sustainability.

Summary table of innovations

| Area | Innovation | Main benefits | Environmental impact |

| Digitalization | Digital and 3D printing | Greater precision and customization | Reduction in production waste |

Advanced materials | High-entropy ceramics, nanocomposites | High mechanical and thermal performance | Long life and lower resource consumption |

| Sustainability | EPD, ISO 14001, material recycling | Greater transparency and traceability | Reduction in emissions and waste |

| Low-emission inks and adhesives | Water-based and ECO formulations | Better air quality and workplace safety | VOC reduction of up to 50% |

| Design and surfaces | 3D textures and digital colors | Advanced aesthetics and technical functionality | Optimized printing processes |

Conclusions

Innovation in the ceramic sector is key to combining technical performance, aesthetics, and environmental responsibility.

Sicer demonstrates that it is possible to evolve towards a more efficient and environmentally friendly production model without compromising on the quality and beauty of ceramic surfaces.

Discover how Sicer’s Low Emission solutions can support your transition to more sustainable production.

FAQ

The most important ones concern digital printing, high-performance materials, and water-based technologies, which improve quality, customization, and sustainability.

It is an ink formulated to drastically reduce emissions of volatile organic compounds (VOCs) and odors during printing and firing, ensuring healthier working environments.

Yes, Sicer Low Emission Water-Based adhesives are designed to work with modern production lines without structural modifications.

Through constant research into eco-friendly inks, effects, and digital adhesives, reduction of emissions, and adoption of production processes that comply with European environmental regulations.

Greater efficiency, reduced waste, production precision, and creative freedom for designers and architects.