- Introduction: the digital adhesive revolution

- What are digital adhesives and how do they work?

- Technical and production advantages

- Types of Sicer digital adhesives

- Adhesion parameters and surface behavior

- Technological evolution and sustainability

- The Sicer approach and digital certifications

- Conclusions and future prospects

- FAQ

Introduction: the digital adhesive revolution

In recent years, digital ceramic decoration has revolutionized the production process, introducing more precise, controllable, and sustainable materials.

Among these, digital adhesives represent one of the most significant innovations: advanced chemical formulations developed to ensure selective and uniform adhesion of grit and technical materials on new-generation ceramic surfaces. For laboratory technicians and R&D managers, the choice of digital adhesive directly affects aesthetic performance, process stability, and environmental impact.

What are digital adhesives and how do they work?

Digital adhesives are adhesives specifically designed to be applied using industrial inkjet printers.

Unlike traditional adhesives, they are digitally deposited only in areas where grit needs to adhere.

How they work

Controlled application allows you to:

- adjust the amount of material deposited (weight 50–90 g/m²),

- optimize fusibility in the oven,

- reduce waste and surface defects.

The result is a more efficient, cleaner, and more precise process, with lower raw material consumption and improved visual and tactile performance of the finished product.

Technical and production advantages

The use of digital glues in ceramic decoration departments offers measurable advantages in both technical and environmental terms.

| Technical parameter | Operational benefit |

| Application precision | Controlled digital deposition |

| Reduced consumption | Targeted dosing and no waste |

| Process cleanliness | No overspray, minimal maintenance |

| Uniform adhesion | Excellent adhesion even on textured surfaces |

| Controlled fusibility | Better spreading and yield of grit |

| Reduced emissions | Significant reduction in VOCs and odorous compounds |

These benefits translate into improved production performance, reduced setup times, and greater aesthetic consistency between batches.

Types of Sicer digital adhesives

The Sicer range now includes three families of digital adhesives, each with specific characteristics in terms of chemical composition, drying times, and intended use.

WATER BASED series

Water-based adhesives are the most sustainable solution in the Sicer range.

They are designed to drastically reduce emissions into the atmosphere, allowing production on multiple lines without exceeding TOC and aldehyde limits.

Main advantages:

- Reduction of VOCs, TOC, aldehydes, and odorous substances.

- Integrated flux that increases adhesion and waterproofs the substrate.

- Long drying times, ideal for complex production lines.

- Natural and anti-reflective effects, without a “plastic effect.”

Main codes:

- SCD3001H (Glossy)

- SCD3993H / SCD3994H / SCD3991H (Matt)

Can be applied to porcelain stoneware in combination with glossy or matt grits to achieve different effects.

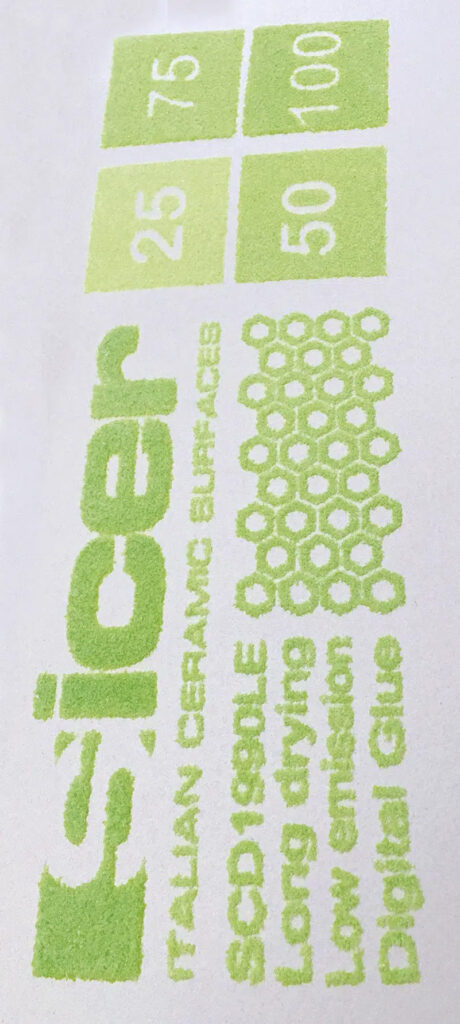

LOW EMISSION (.LE) series

The patented eco-solvent-based digital adhesives of the .LE series represent an ideal balance between performance and sustainability.

The formulations reduce formaldehyde emissions by over 50% and the TOC value by 20% compared to traditional ester-based products.

Main advantages:

- High fusibility and grain spread.

- Almost zero odor emissions.

- Medium-long drying times for stable and clean adhesion.

- Ideal for full-field or graphic applications.

Main codes:

- SCD1990LE (Glossy)

- SCD1992LE / SCD1993LE (Matte)

.A series – Glycol ether-based

The .A series introduces a glycol ether-based formulation, designed to minimize emissions of fumes and odorous compounds from the chimney.

These are flux-based adhesives with excellent fusibility and compatibility with the most modern digital systems.

Main advantages:

- Significantly reduced fume and odor emissions.

- Medium-long drying time for high weights.

- Thermal stability and controlled adhesion even on difficult substrates.

Main codes:

- SCD4001A (Glossy)

- SCD4010A (Matte)

For further information, download the complete guide to Sicer digital adhesives.

Adhesion parameters and surface behavior

The performance of digital adhesives depends on a combination of physical and chemical factors:

- Surface tension (mN/m): influences the ability to wet the substrate.

- Viscosity (mPa·s): determines the regularity of the jet and the precision of the print.

- Drying time: must be balanced to ensure optimal adhesion without dripping.

- Thermal compatibility: essential to avoid residues or color changes during firing.

In Sicer’s laboratories, these parameters are always checked to ensure stability, repeatability, and constant fusibility.

Technological evolution and sustainability

Sicer digital adhesives embody the philosophy of “Continued Innovation & Environment Respect.”

Each formulation is the result of applied research aimed at reconciling industrial performance and environmental protection.

- Reduction of VOC and TOC emissions.

- Simplified plant engineering, thanks to compatibility even with lines without afterburners.

- Improved air quality in the department and operational comfort.

Research into sustainability concerns not only chemistry but also the final product.

The Sicer approach and digital certifications

Thanks to its comprehensive range—WATER BASED, LOW EMISSION, and .A—Sicer is now a global technology partner for ceramic companies seeking high performance and true sustainability.

All digital adhesives are certified and approved by leading digital machine manufacturers, guaranteeing compatibility, reliability, and process consistency.Learn more about Sicer’s solution: Low Emission Digital Glue – Water Based

Conclusions and future prospects

Digital glues are a key technology for the contemporary ceramic industry: greater efficiency, less waste, greater sustainability.With the brand new WATER-BASED series, Sicer further consolidates its role as a leading partner for the ceramic industry, offering solutions that combine advanced chemistry, process control, and environmental friendliness.

FAQ

Adhesives formulated for digital application with inkjet printers, used to fix grit and technical materials to ceramic substrates.

Greater precision, reduced waste, controlled adhesion, and lower emissions into the atmosphere.

– Water Based: water-based, sustainable.

– Low Emission (.LE): patented eco-solvent base.

– .A: glycol ether-based, to reduce odorous fumes.

Yes, they are approved by the leading manufacturers of digital machines.

By reducing VOCs, formaldehyde, and odorous compounds, without sacrificing aesthetic or production performance.