Index

- Introduction

- Technical requirements for garage ramp flooring

- Ideal materials for non-slip tiles in garage ramps

- Specific technical solutions for ramps

- Aesthetic considerations when choosing tiles

- Specific considerations for different types of ramps

- Installation and technical expedients

- Maintenance and durability

- Cost and value for money

- Conclusions and buying advice

Introduction

Garage access ramps represent areas subject to high mechanical and environmental stresses. Rain, ice, slope, and vehicular traffic make it necessary to have flooring that is not only durable, but above all slip-resistant. The goal is to strike a balance between safety and aesthetic performance, avoiding improvised solutions that could compromise functionality or durability.

Technical requirements for garage ramp pavements

When designing a driveway ramp, it is critical to consider:

- Recommended anti-slip ratings for slopes (at least R11 or R12, better R13 for exposed or very steeply sloping ramps);

- The minimum coefficients of friction recommended by standards (e.g., EN 16165, DIN 51130);

- The resistance to loads: the material must withstand the repeated passage of vehicles without deforming;

- Tire wear, especially in braking or turning areas.

Ideal materials for non-slip tiles in garage ramps

Better options include:

- Technical porcelain: compact, chemical-resistant and available in R12 or R13 finishes;

- Industrial Klinker: excellent mechanical strength and good natural grip;

- Textured cement: ideal for continuous surfaces, can be treated with resins;

- Epoxy resins with aggregates: create a continuous coating with high-adhesion inserts;

- Prefabricated modular systems: innovative solutions for removable or temporary ramps.

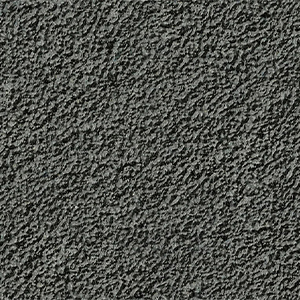

A case in point is Sicer’s NEXT EXPERIENCE SURFACES line, a ready-to-use mix of micro grits that provides opaque, anti-reflective and highly slip-resistant surfaces (up to R12), ideal for high-risk outdoor environments such as driveway ramps. The product combines chemical resistance, ease of cleaning, and a textural texture that does not compromise aesthetics.

Specific technical solutions for ramps

In addition to the choice of material, security can be increased with:

- Embossed textures, grooves or abrasive inserts;

- Post-lay surface treatments that improve adhesion;

- Drainage systems to prevent stagnation;

- Solutions for bends and fittings, where adherence needs to be even higher.

Aesthetic considerations in choosing tiles

Safety and design are not at odds. It is possible:

- Choose colors that mask dirt and wear;

- Use matte finishes that reflect less light and increase visibility in critical conditions;

- Integrate functional patterns (e.g., guidelines, staging areas);

- Coordinate the coating of the ramp with that of the building.

Specific considerations for different types of ramps

Each context has its own needs:

- Residential: priority to aesthetic discretion and durability;

- Condominium: modular and high traffic resistant solutions;

- Blankets: attention to cleanability and tire resistance;

- Discoveries: materials certified R12 or R13, resistant to frost and moisture;

- Steep ramps: use of grooved tiles, extreme grip, and integrated drainage systems.

Installation and technical expedients

The effectiveness of a flooring also depends on the installation:

- The subgrade must be perfectly level and draining;

- Expansion joints should be sized according to the expected temperature range;

- Slopes must ensure water runoff;

- Sealing must withstand fuels and de-icing salt.

Technical sections illustrating proper installation on sloping surfaces

Maintenance and durability

Good flooring is that which maintains its characteristics over time:

- Cleaning with neutral detergents or non-oily degreasers;

- Removal of oil or fuel stains with specific products;

- Resistance to frost, deicing salts and chemicals;

- Annual checks for integrity of joints and slopes.

Cost and value for money

The factors that affect the final price are:

- The material chosen and its certifications;

- The complexity of laying (slope, fittings);

- The extent of the surface area;

- Any additional treatments (antifreeze, drainage).

Conclusions and purchase advice

Choosing slip-resistant garage ramp tiles is a decision that impacts daily safety, durability, and aesthetic integration of the entire building. The advice is to carefully consider:

- The required anti-slip classification (R11-R13);

- The climatic conditions of the context;

- The type of traffic expected;

- Aesthetic compatibility with the surrounding environment.

Sicer offers advanced technical solutions such as NEXT EXPERIENCE SURFACES, developed to meet the highest standards in terms of safety, aesthetics and durability.